| Sniper IIThe Sniper II includes a sixteen (16) profile, sixteen (16) segment controller, which is easily programmed using an integral key pad. Alternatively the system can be controlled via an RS232 connection with an optional external computer.

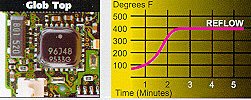

Graphical Display Window (GDW)

The optional computer software operates in a Windows based PC environment. Profile Pattern Recipes (PPR) are easily created, stored, recalled, and edited using a “Graphical Display Window” (GDW). Programs are automatically up loaded to the Sniper II controller. Any number of PPR’s may be stored for future recall.

Computer Operation

Programs may be controlled and operated directly from the optional computer and a graphical chart of the temperature profile traced in “Real Time”

Simple Operation

It is not necessary to use the computer for general operation. To run a PPR, the operator simply selects the PPR from the Controller panel and presses the “Run” key. The program is then run automatically. The operator need not be in attendance during the reflow process.

Bottom heat control

The bottom heater is controlled by the top reflow controller. The top and bottom Heaters are automatically switched off after the rework program is complete.

Data Logging

Once the rework operation is completed, the event may be automatically “Data Logged” using Adobe.pdf graphical images. These are easy to read and can be communicated via the internet.

Download The Video-

APE also offers video narrated trials to help in the evaluation process, our lab technicians will perform your job and return the completed work with the video.

|

Thermal Tracer

The optional APE Thermal Tracer tracks up to six (6) sensors, which can be strategically located at and around the component. The sensors are used to develop a “Profile Pattern Recipe,” indicating the actual board temperatures during the rework process. The system can also be used to calibrate the Sniper hot air delivery. The 8300-9660 is supplied as a PCMCIA Card for insertion in a Lap Top or within the Card Reader option.

Sniper & Sniper II Order Information

Sniper I (Government Only Model)

- 7007-1000 Sniper 110V 60Hz

- 7007-1002 Sniper 220V 50Hz Bottom heat control

- 7000-1216 PCB Holder Extension Kit 12″ x 16″ (305 x 406mm)

- 7000-2500 Macro Image Diagonal Splitter

Sniper II- PC and software optional

- 7007-5001 Sniper II 110V 60Hz

- 7007-5002 Sniper II 220V 50Hz

- 7000-1216 PCB Holder Extension Kit 12″ x 16″ (305 x 406mm)

- 7000-1250 APE configured PC and GDW software

Thermal Tracer

- 8300-9660 Thermal Tracer Software and PCMCIA Card (5 sensors)

- 8300-9661 PCMCIA Card Reader Adapter

|

Shop Online

Shop Online